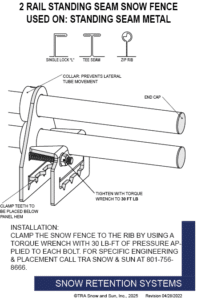

Description

Used on: Standing Seam Metal Roofs

• Available for all rib types including: Single Lock, Tee Seam, Zip Rib, etc.

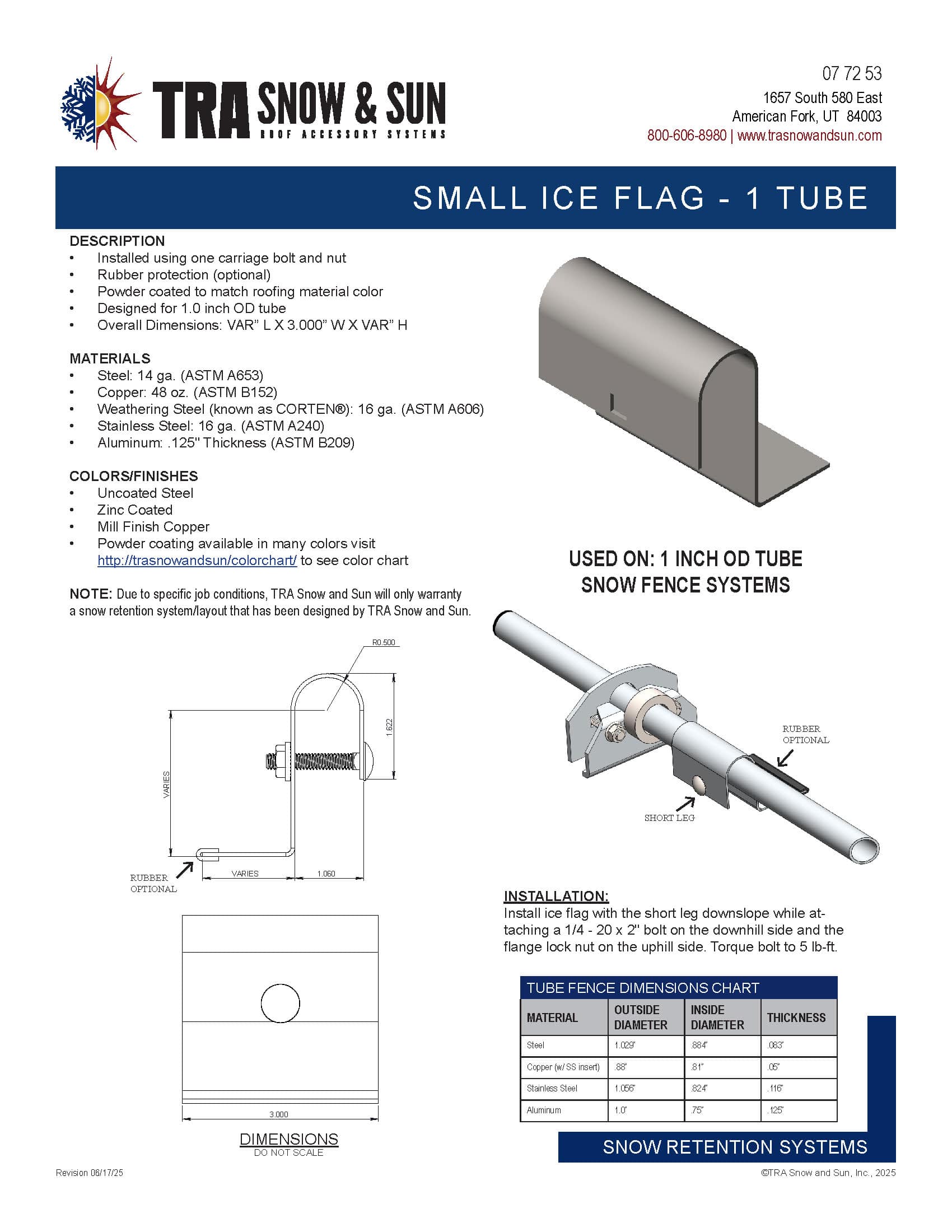

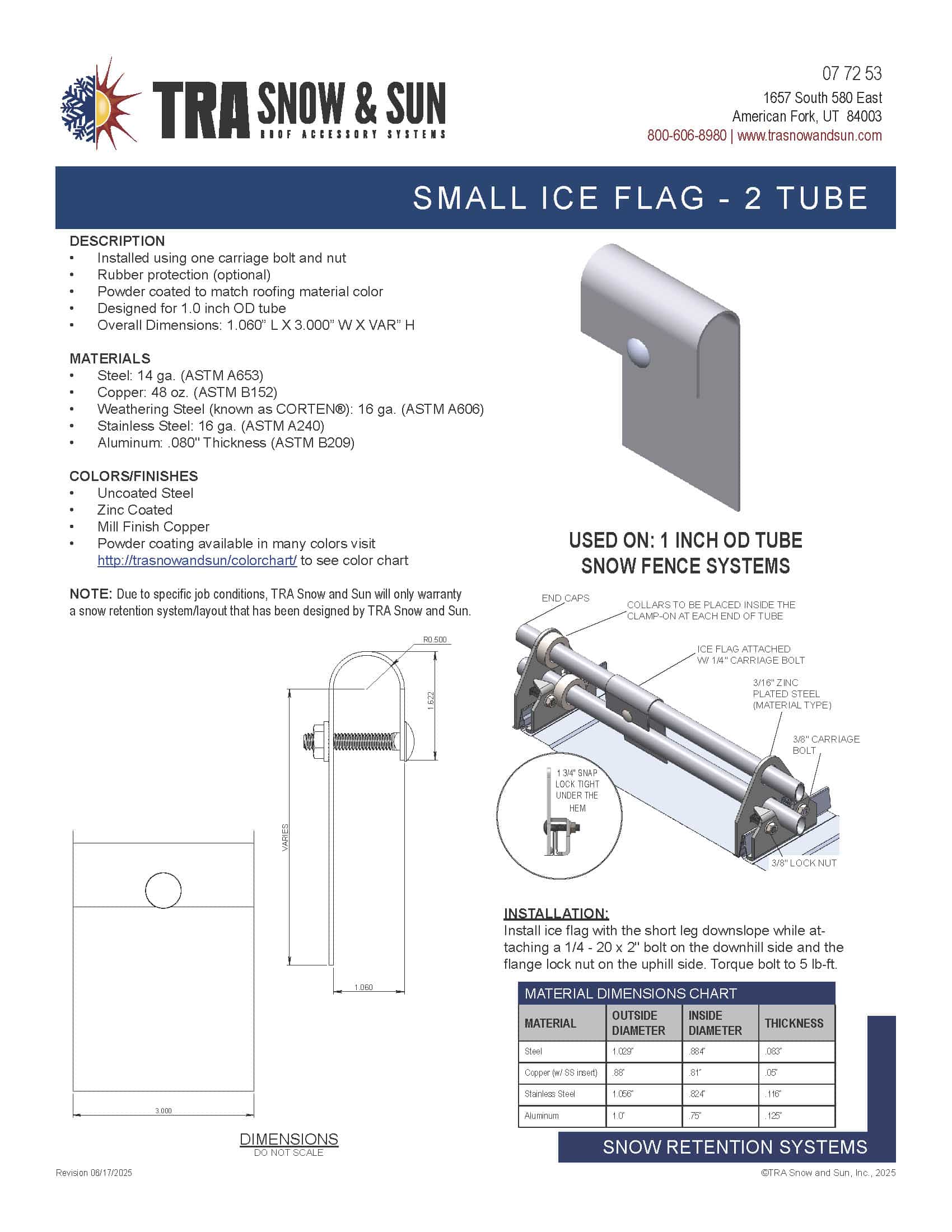

• Designed for 1.0″ OD tube

• Allows for full installation without any penetration of the roof surface

• Powder coated to match roofing material colors

• Overall dimensions: 5.19″L X 1.93″W X VAR”H

• Height of clamp varies based on rib type and height

• Carriage bolt (2) 3/8” Dia X 1-3/4” or 2”

• Ice Flags (recommended)